Managing the effects of parasites on stock is a key factor in farming profitability. Younger animals are impacted most by the number of worm larvae they consume, yet parasites thrive in the warm wet conditions we need to grow high-energy pasture.

Every drench is a chance to remove the parasites lambs have consumed since they were last treated effectively, but more and more often our go-to products are leaving breeding worms behind. This resistant population shows up first as eggs in a Faecal Egg Count (FEC), and eventually with stock that are failing to thrive (or even survive!).

It is the substitution of one routine lamb drench for a high-efficacious novel drench product, usually either Startect® or Zolvix™ Plus.

Both are novel drenches which contain a new drench active, monepantel and derquantel respectively, and these are combined with abamectin to give a double combination product.

Using knockout doses of novel drenches (Startect® or Zolvix™) is a key tool for tackling these resistant worms, by exposing them to a chemical to which they have no immunity. As well as lifting the health of the animals we treat, we are aiming to halt the shower of resistant parasites onto pastures where we want to grow young stock. Lastly, we are trying to preserve the usefulness of our regular drenches, by ‘knocking out’ the worms that survive the drenches we rely on the most.

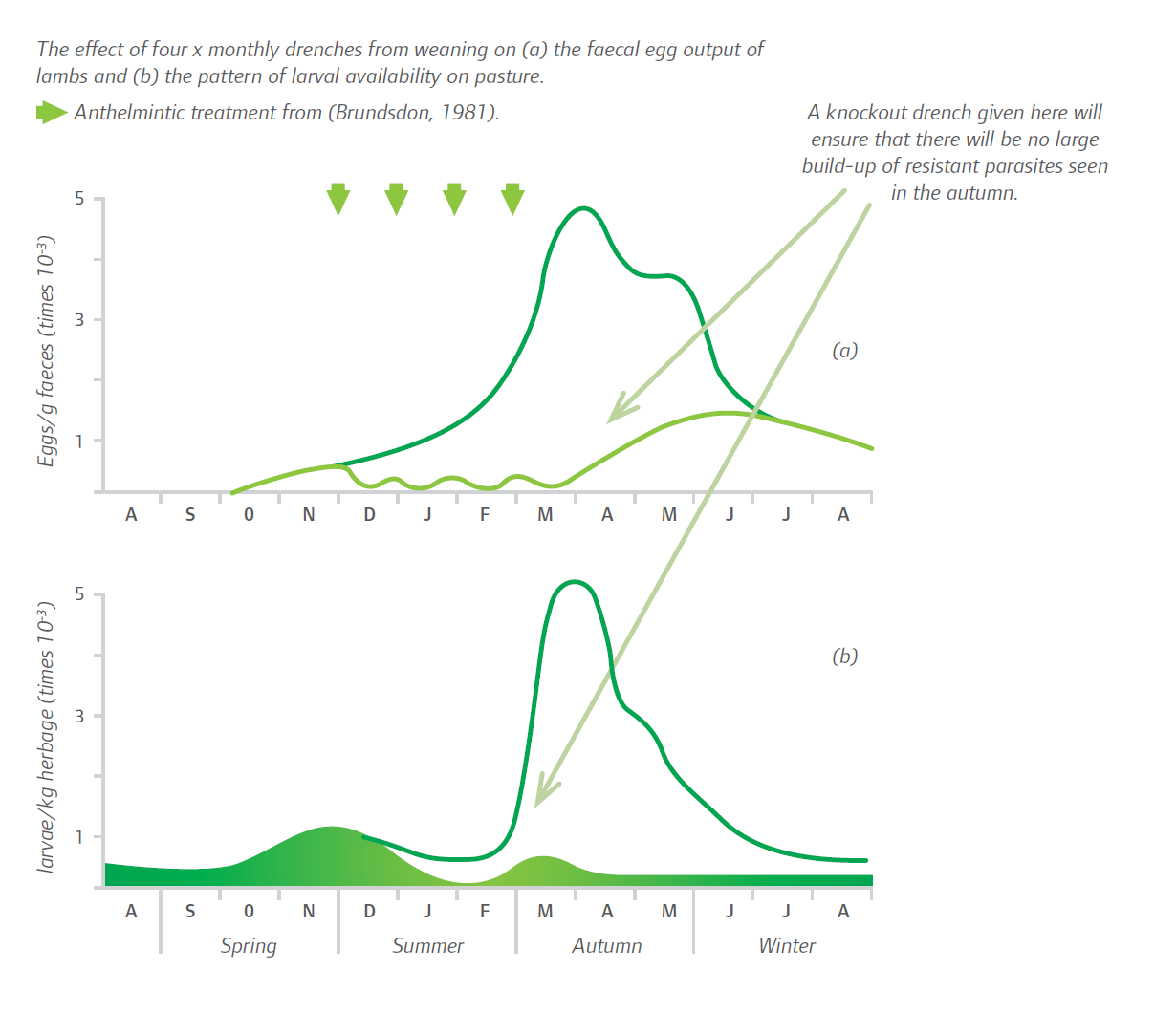

In short, knockout drenching is done to remove any resistant parasites which have survived routine drenching. Thus we can prevent them from causing an autumn peak involving resistant larvae which would leave a resistant population to seed next season’s worm challenges.

It has also been shown to delay the onset of resistance to existing routine drenches by reducing the period of reproductive advantage for resistant parasites over susceptible parasites.

The ability of worms to develop immunity to chemicals over time does mean we need to guard the use of these novel drenches, and not use them in place of each of our regular drenches. So how do we decide when to reach for the ‘big guns’?

While a knockout drench can be given at any time, each system and season will have an ideal time to treat, but initially, you want to find a time when resistant parasites have built up in young stock. The best time is when conditions become favourable for larval survival and development on pasture (i.e. when it is warm and humid).

Often this will be late summer and into the autumn. Drench checks (10 days post-drench FECs) will often flag the problem before stock start to ‘go off’.

If they are grazing pastures where lambs and calves will continue to feed, and the temperature and moisture levels suit good pasture growth (and therefore worm larval development), then this is a good time to use the knockout drench.

The classic time for use would be at the end of a 5-6 drench programme for ewe replacement lambs or for any other lambs still on farm that have had regular oral drenches since weaning.

If your farming system is reasonably consistent, and drench checks have shown that you are not yet developing resistance, then using knockout drenches once or twice a season should be sufficient. If you have already identified resistance or you run a higher risk system (trading, intensive finishing), then you may need to monitor throughout the season, and possibly come in several times with a knockout drench.

Resistance can develop to all chemicals, and drench checks should be carried out 10-14 days after Zolvix™ or Startect® are used, to make sure we are achieving our set goals. In high-contamination farming systems, it is possible to generate resistance to novel drenches in just a few seasons! This is a reminder that a whole-of-farm approach is needed when considering drench resistance, with chemicals only being one part of the equation.