Cut, compact, and cover – the 3 very important rules for making quality silage, especially in today’s expensive feed world.

I thought I would take the time here to discuss some of the important aspects of silage production that will ensure you can get good high-quality silage that is well suited as a supplement for milk production.

The production of silage is a very big topic, so I will focus on the production of high-quality silage for milk production in particular. The timing of cutting silage is very important because ‘quality in’ always equates to ‘quality out’, and of course, no matter what we do, the quality of the silage is always lower than the quality of the pasture cut – no such thing as a free lunch!

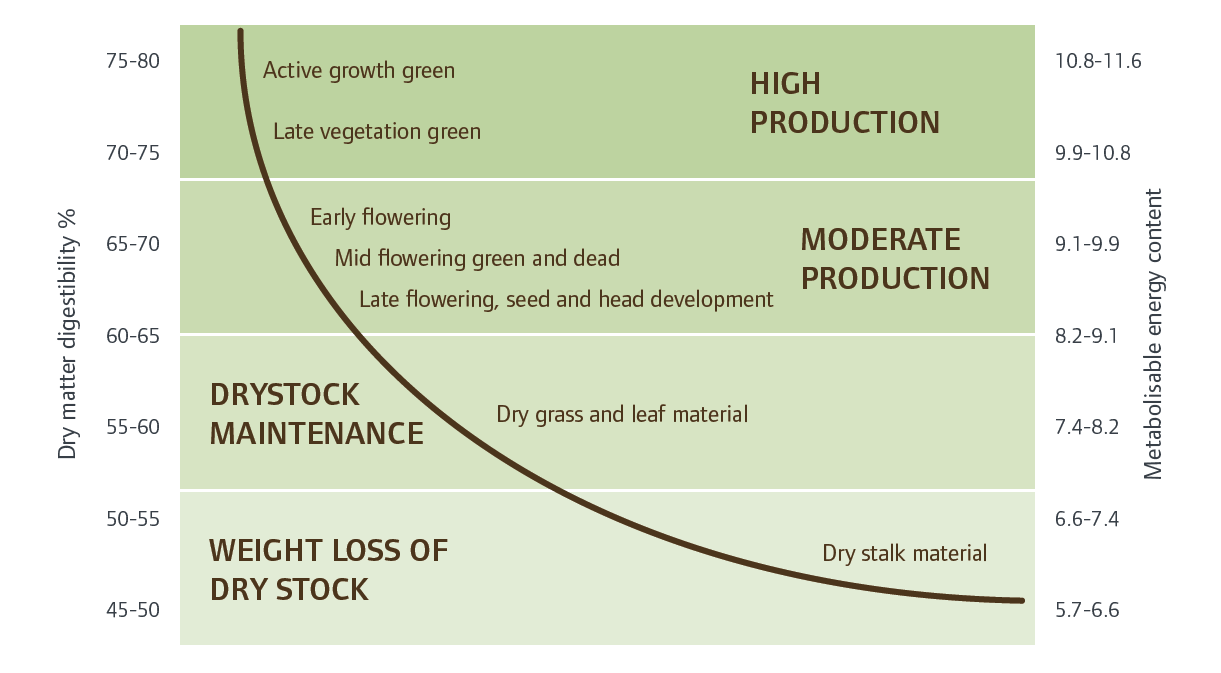

Figure 1. shows the quality content and range of expected production levels from typical ryegrass and white clover stand with a declining ME content and dry matter digestibility (DMD%). As producers, if you want to use silage as a high-quality supplement, you need a minimum ME of 10.5 and a minimum crude protein content of 15%.

Figure 1. Anticipated animal production levels from ryegrass and white clover pasture at different stages of maturity; Adapted from Bell, (2000)

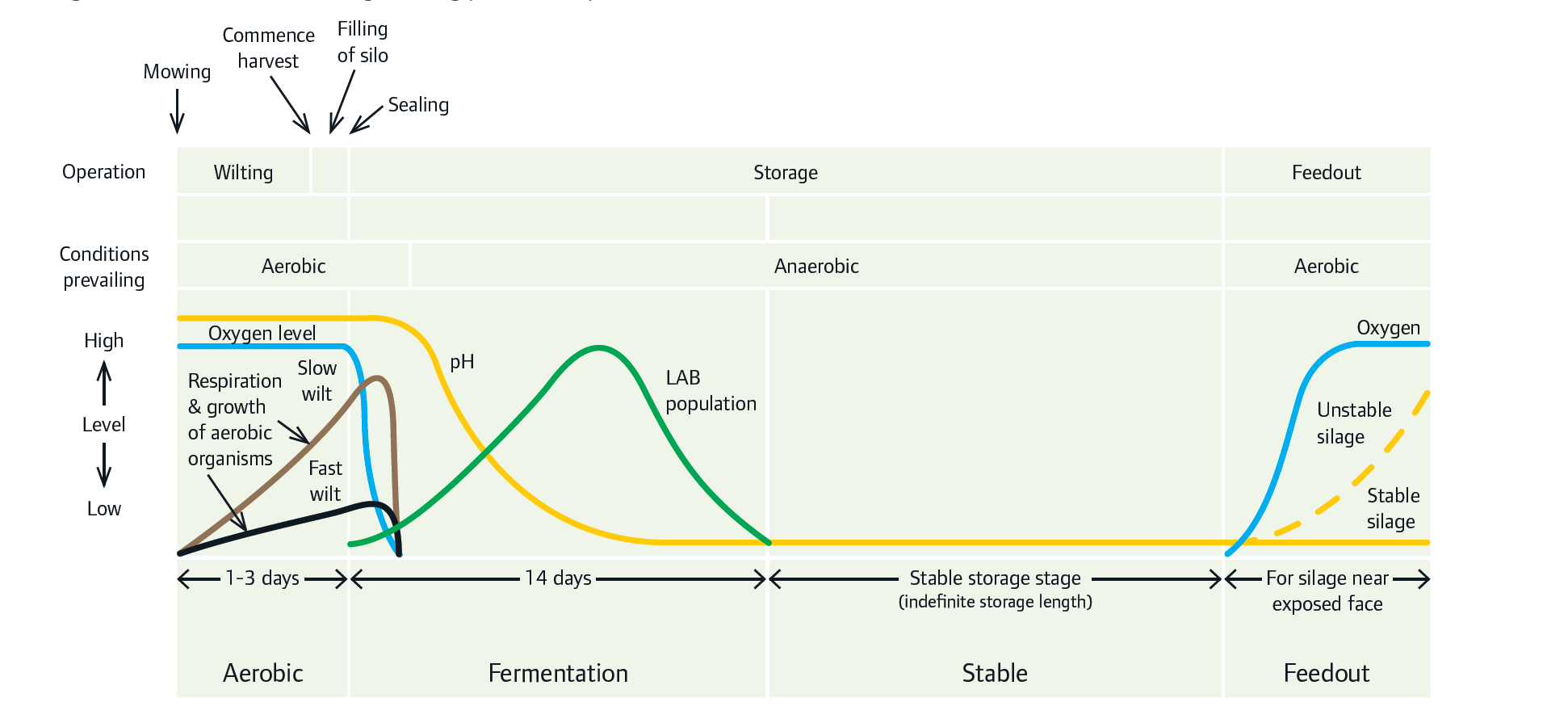

Wilting of cut pasture is important for losing excess moisture from the crop as well as improving the concentration of water-soluble carbohydrates (WSC) in the cut grass. The WSC content of cut grass is very important as it is these sugars that the bacteria utilise to ferment the pasture and turn it into silage once it is placed into the stack. You want the good bacteria which produce lactic acid (LAB) – these critters are not fans of oxygen, so that is why stacks are compacted and sealed to squeeze and keep out available air from the cut pasture to ensure we create an environment where the bacteria can work their magic and ferment the grass (Figure 2.)!

Once the stack is covered and compacted, these LAB do their thing by fermenting the available sugars and reducing the pH in the stack. Fortunately for us, but unfortunately for them, they are so efficient at fermenting the feed into silage that they reduce the pH to a level that kills them all, hence the stack becomes preserved within a period of around two weeks.

Figure 2. A schematic of the silage-making process; Adapted from Pitt (1990).

Keeping silage clean from soil contamination is important to minimise the population of less desirable species of bacteria – these can use up the available feed which in turn reduces the quality and quantity of preserved silage.

As we all know, once the stack is opened for any period, the front becomes manky with the prolific growth of aerobic bacteria and fungi, and some of these organisms can produce toxins that can cause a wide range of animal health issues. Therefore it is best to discard this unhealthy section and keep the stack covered as much as is practically possible.

There is a range of inoculants available on the market. In some situations, generally, where anticipated feed quality is likely to be poor, they can be of benefit to improve feed quality, and this in turn improves animal voluntary feed intake and hence animal performance.

However, the resultant improvement in animal performance in most of the studies carried out internationally can be marginal, so ask the contractor for evidence that the inoculant works before going down that road.

Remember, high quality in equals slightly lower quality out, so how the silage is treated between cutting and ensiling can make all the difference! Treating silage production as an investment for the future – rather that a job to be done on a wing and a prayer – is vital if you want good quality silage to be used as a supplement to aid in milk production.